Steel Structure factory Manufacturing

Item No.:

Gg-09Payment:

T/T & L/CProduct origin:

Hebei, ChinaShipping port:

TianjinLead Time:

about 30 daysPrice:

30-50 usd/sqmProduct description

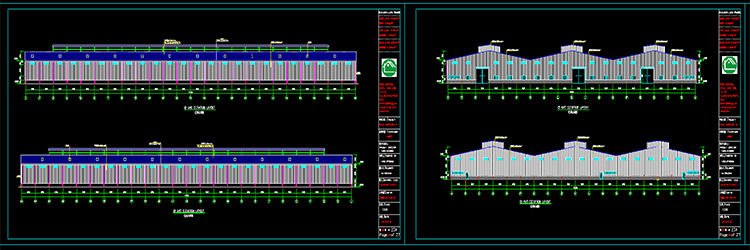

The steel structure workshop size: 150m x 108m x 8m

Material:H-beam

Wall/Roof:Sandwich panel/steel tile

Wind load: 0.3KN/m2

Live load: 0.3KN/m2

Dead load: 0.15KN/m2

Earthquake:8 grades

Our steel structure has a wide range of uses. In addition to factories, it can also be used as warehouses, workshops, production workshops, office buildings, exhibition halls, etc. As long as you have any needs, please feel free to contact us.We have professional designers who can provide you with free design solutions according to your requirements.

Steel structure production process

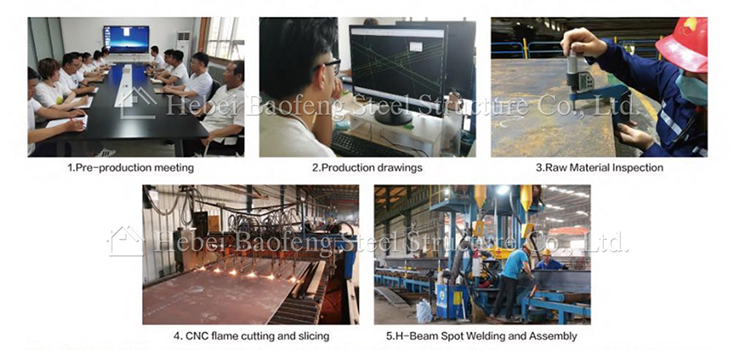

1. Pre-production meeting: Discuss project requirements and execution standards, ensuring customer’s demands are accurately forwarded to the production line.

2. Production drawings: With quality requirements and process standards.

3. Raw Material Inspection: Rigorous inspection of raw materials ensures qualified products entering the factory.

4. CNC flame cutting and slicing:High Precision and high production efficiency make the steel cutting amount per day up to 150-200 tons.

5. H-Beam Spot Welding and Assembly: Assembled welded and corrected in a streamlined process with a production rate of approximately 25 meters per hour.

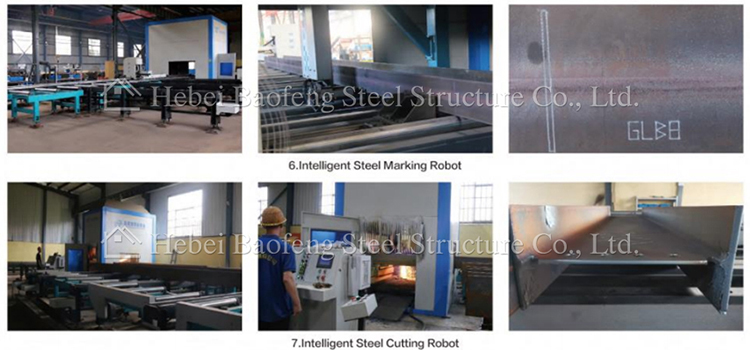

6. Intelligent Steel Marking Robot: Smart operation for precise line marking.

7. Intelligent Steel Cutting Robot: Infrared ray scans marking, accurate cutting. Perfect finish, efficient cuts up to 50 tons.

8. Small Plates Fabrication: Automated CNC machines, ensuring high-speed, accurate drilling to guarantee error-free installation.

9. Assembly: Connected plates are assembled and welded on H beam, Cross work maximize welding efficiency.

10. Shot Blasting: Sa 2.5 grade clean rust and enhance coating adhesion, extend life usage.

11. Semi-Finished Product Inspection: 100% quality inspection to ensure product compliance.

12. Painting: Four coats of paint , ensuring a smooth, bubble-free, crack-free, and uniform surface finish.

13. Product Coding: Every steel structure part is clearly coded according to installation drawings, ensuring smooth installation.

14. C-Steel Production: CNC programming ensure smooth, high-efficiency production, yielding 5,000 meters daily.

15. Single Panel Production: Six machines produce 10,000 meters daily, high efficiency.

16. Composite sandwich Panel: High-speed production of 2,000 meters daily.

17. Bending: Accessories and gutters for the entire facility are fabricated here.

18. Finished Product Inspection: Goods can not be allowed to be packed until getting the approval by QC Authorities.

19. Storage: Qualified products are categorized and stored in the yard, to keep the goods are clean, dry and ventilated.

20. Packaging: packed with steel crates, save shipping container.

21. Pre-loading Inspection: Quantity and appearance inspections are conducted before loading, ensuring customers can receive the perfect goods.

Benefits Of Prefab Warehouses

A metal warehouse building kit with an optimized layout not only utilizes space better, but it boosts productivity while saving money. The key is to design the flow of inventory, material handling equipment, and people to suit the products and volumes moving through the warehouse. The better a layout caters to these, the smoother the logistics process.

Metal buildings are perfect for warehousing purposes because they’re affordable and quick to erect. Additionally, these structures can support heavy loads and be built to just about any width, height, and depth. As a result, it’s easy to accommodate a variety of storage needs.

The steel used for the frame, wall panels, and roofing system is resilient to fire, wind, moisture, and mold. Insulated wall or ceiling panels offer superior thermal protection capabilities, helping maintain interior climate control regardless of external weather conditions. This keeps employees comfortable and stored items safe, which leads to greater customer satisfaction.

If you need to build steel structure building, contact us.

Previous :

Two-span prefabricated light steel build quick build cheap steel structure warehouseNext :

Long span steel frame garment factory building in KenyaIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Modern design steel frame building prefabricated construction steel structure material warehouse for sale Read More

Large span weld H beam prefabricated steel structure workshop made in China Read More

Prefabricated light steel structure storage warehouse buildings made in China Read More

Prefabricated luxury living expandable container house Read More

Customized Steel Structure Two-story chicken coop exported to the Philippines Read More