Application of H beam in steel structure building

The H-beam is a fundamental and ubiquitous component in steel structure buildings, prized for its exceptional efficiency in carrying loads. Its application is vast, forming the literal "skeleton" of modern structures.

Here’s a detailed breakdown of the application of H-beams in steel structure buildings.

What is an H-Beam?

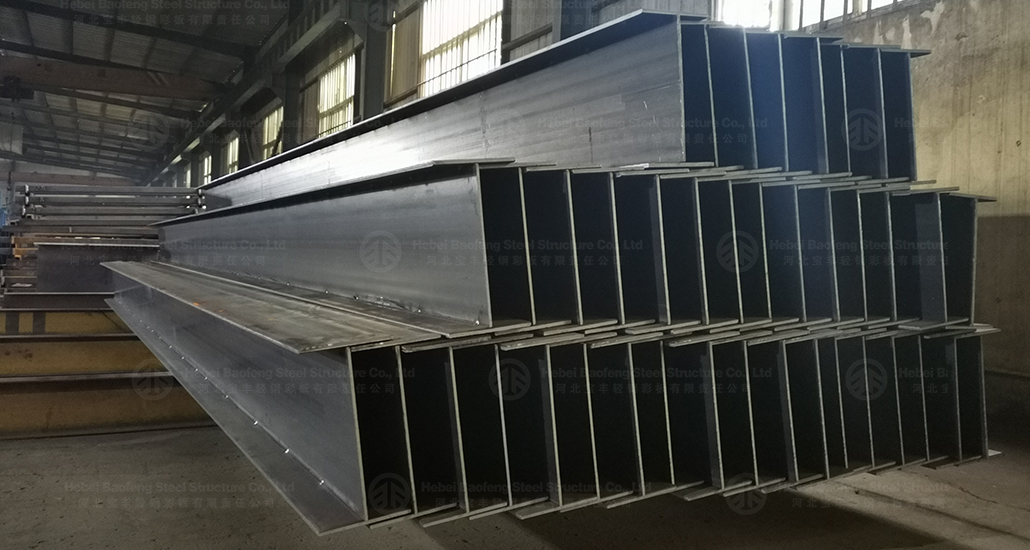

An H-beam, named for its cross-section resembling the letter "H," is a rolled steel joist. It consists of two horizontal elements (the flanges) connected by a single vertical element (the web). This shape is engineered to provide superior strength-to-weight ratio.

Key Parts:

Flanges: The top and bottom parts. They are wider and primarily resist bending moments.

Web: The vertical part connecting the flanges. It primarily resists shear forces.

The most common international standard for H-beams is the Wide Flange Beam (W-beam), which is what people typically refer to when talking about H-beams in construction.

Key Applications in Steel Structure Buildings

H-beams are used in virtually every major element of a steel-framed building.

1. Primary Framing (The Main Skeleton)

This is the most critical application, where H-beams carry the primary loads of the building.

Columns (Vertical Members):

Application: H-beams are the preferred choice for vertical columns, particularly Wide Flange (WF) sections. The nearly equal flange width provides excellent load-bearing capacity in all directions, making the columns stable against buckling.

Advantage: Their symmetrical shape makes connections to beams straightforward and allows them to handle moments and axial loads from multiple directions efficiently.

Girders and Beams (Horizontal Members):

Application: Large H-beams are used as primary girders that support smaller beams and the floor system. Smaller H-beams are used as floor beams and roof purlins (though cold-formed C- or Z-sections are also common for purlins).

Advantage: The flanges are positioned at the top and bottom, where bending stresses are highest. This design makes H-beams incredibly efficient at spanning long distances and supporting heavy loads (like floors, equipment, and cranes) with minimal material.

2. Floor and Roof Systems

Floor Beams: H-beams form the primary support for the floor deck (often made of corrugated steel). The concrete slab is then poured on top of the deck, creating a composite floor system.

Roof Support: They are used as rafters and girders to support the roof structure, including the roof deck and insulation.

3. Specialized and Heavy-Duty Structures

The strength of H-beams makes them ideal for demanding applications.

Industrial Buildings: Warehouses, factories, and power plants. They are essential for supporting heavy machinery, crane runways, and large, clear-span spaces without obstructive columns.

Commercial Buildings: High-rise buildings, shopping malls, and airports. They provide the framework for large open areas like atriums and concourses.

Bridges: While often using even larger plate girders, the principle is the same—H-beams are used for the main girders that support the bridge deck.

Mezzanine Floors: H-beams are the go-to choice for the primary supports of intermediate floors within a high-bay space.

Advantages of Using H-Beams in Construction

The widespread use of H-beams is due to a combination of structural and practical benefits:

High Strength-to-Weight Ratio: They offer maximum strength with minimum weight, reducing the load on foundations and making transportation and erection easier and more economical.

Excellent Load-Bearing Capacity: The design is optimal for handling both bending (from gravity loads) and axial compression (in columns).

Ease of Fabrication and Connection: Their uniform, flat surfaces make them easy to cut, weld, and bolt. Connecting beams to columns or other beams is simpler compared to irregular shapes.

Design Flexibility: Available in a vast range of standard sizes (with varying depth, flange width, and weight), allowing engineers to select the most efficient section for a specific load and span requirement.

Predictable and Reliable Performance: As a standardized, rolled section, their mechanical properties are well-understood, which simplifies engineering calculations and ensures safety.

Conclusion

The H-beam is the backbone of modern steel-structured architecture. Its efficient geometric shape provides an unparalleled combination of strength, versatility, and cost-effectiveness. From the columns that rise from the foundation to the beams that support every floor and roof, the H-beam's application is fundamental to creating the strong, flexible, and expansive spaces that define contemporary buildings.

Categories

latest blog

Tags