Our steel chicken coops are designed to be durable, low maintenance, and ensure long-term use and protection from the elements.

Item No.:

js-10-cmj-GPayment:

T/T, L/CProduct origin:

Hebei,ChinaShipping port:

Tianjin portLead Time:

about 30 daysPrice:

29-39 usd/sqm

Product description

|

Product |

Steel Structure Poultry House |

| Size | Customized according to customer needs |

| Main Steel | Q235, Q235B, Q345, Q345B etc. |

| Column&Beam | Welded or hot rolled H-section |

| Wall/Roof | Sandwich panel(EPS/PU/glass wool)/steel tile |

| Ventilation | Yes |

| Equipment | As customers' need |

| Connection | Welding connection or bolt connection |

| Surface | Hot dip galvanized or painted (can be customized) |

| Feed type | With cage or free range |

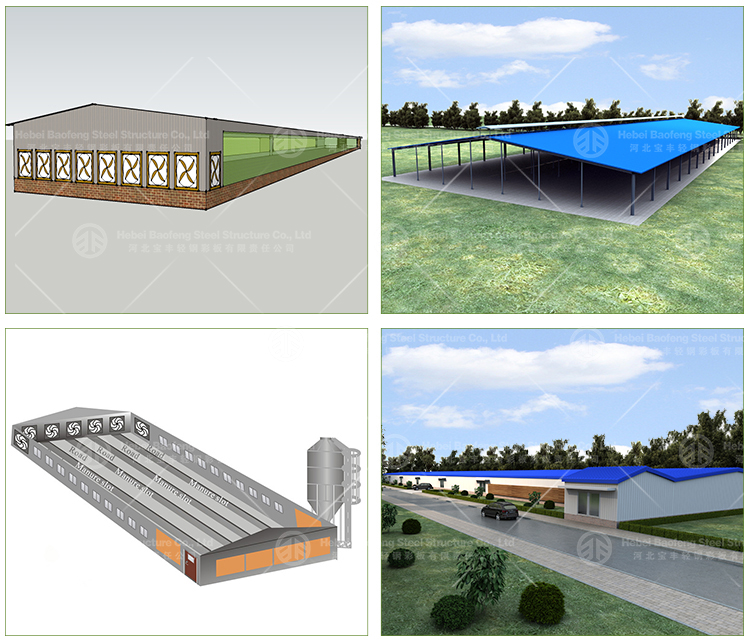

1 FRAME

High humidity and more ammonia can easily lead to some of the facilities corrosion. So we use galvanized H beam for columns and beams. We also use galvanized C beam for purlin. The galvanized frame can protect from being corroded thus can extend the life of the structure. Poultry shed in coastal city demand building have good wind resistance We can design by the advanced software.

2 PANEL

Depending on the climate in different regions, you can choose veneer or insulation composite panel. The steel chicken house plates have a variety of options colors. The board of tile can have a wide selection. Sandwich panels have EPS, glass fiber, rock wool. The panel can be heat insulation and prevent rust and corrosion. lf you don't want to use the panel, you can use the wire mesh for wall. ln hot or cold areas, we recommend to use composite panels, therma insulation and heat insulation. Of course, the veneer price will be lower.

3 HEIGHT

Generally, if the poultry farm is free range farming, the height is 2m-3.5m. lf it is cage farming, the height should be determined according to the number of cage layers.

4 PRODUCTION TIME INSTALLATION TIME

About 3,000 square meters of the poultry shed, from design to sourcing to production finally ended is about a month.

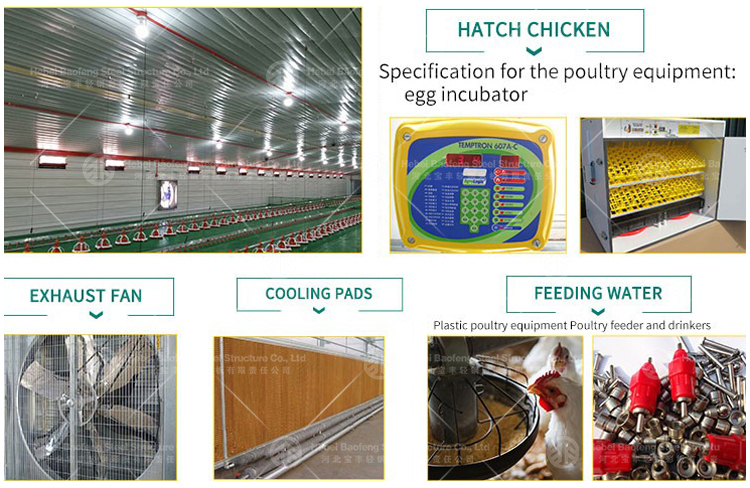

5 PROVIDE VARIOUS TYPES OF ANCILLARY FARMING EQUIPMENT

Drawings & Quotation

1) Customized design is available.

2) We can design and provide drawings for you if it is necessary.

3) In order to give you an exact quotation and drawings, please let us know the length, width, eave height of your projects. We will quote for you promptly.

We have professional designers who can provide you with free design solutions according to your requirements. So, if you have any needs, you can contact us at any time.

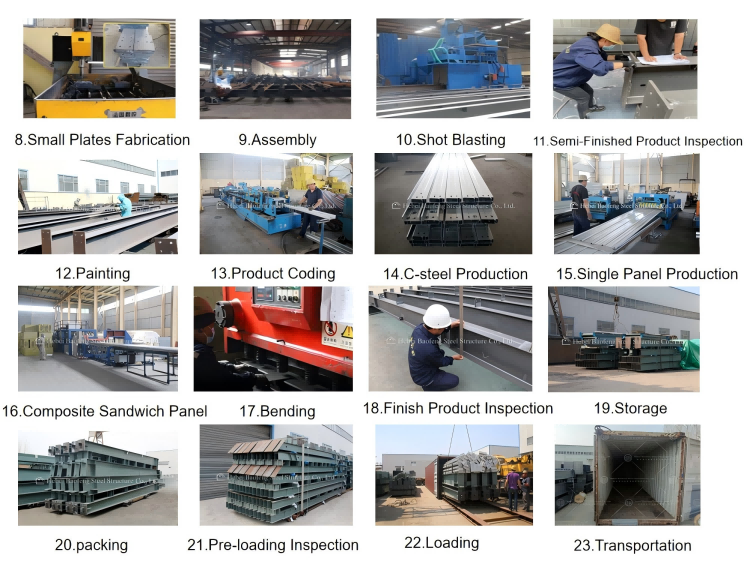

Production process

Certificate

Customer photo

FAQ

Q1: Are you a manufacturing factory or trading company?

A: We are the direct manufacture of steel structure buildings. we have rich experience in steel structure designing, manufacturing, processing, and installation.

Q2: Is your price competitive with other companies?

A: Our business goal is to give you the best price with the same quality and the best quality with the same price. We will try our best to reduce your cost.

Q3: Do you offer service for installation?

A: We will give detailed installation drawings and videos for free. And if you need, we could send engineers as installation directors even a team.

Q4: Do you accept container loading inspection?

A: You are welcomed to send an inspector, not only for the container loading but any time during the production time.

Q5: Do you offer designing service for us?

A: Yes, we have an experienced design team, and we can design full solution drawings as per your requirements.

Q6: What is the delivery time?

A: Delivery time depends on order quantities. Generally, the delivery time will be 30 days after receiving the deposit.

Q7: How can you get a quotation for your projects?

A: You can chat with us anytime or you can just fill out our questionnaire and send it back to us. We will give you the best quotation asap.

Previous :

Baofeng Steel structure chicken house for agriculturalNext :

China Supply Prefabricated chicken poultry house for farmIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Modern design steel frame building prefabricated construction steel structure material warehouse for sale Read More

Large span weld H beam prefabricated steel structure workshop made in China Read More

Prefabricated light steel structure storage warehouse buildings made in China Read More

Prefabricated luxury living expandable container house Read More

Customized Steel Structure Two-story chicken coop exported to the Philippines Read More